- Achieve Software Excellence through our Process Transformation Solutions

Our Solutions

An Integrated Process Framework Driven Approach for

Software-Defined Mobility Success

Our IPF (Integrated Process Framework) seamlessly incorporates ASPICE, Functional Safety, and Cybersecurity in an adaptable plug-and-play approach tailored to your requirements.

Automotive SPICE

Focusing on system and software process improvements with strong adherence to safety and security.

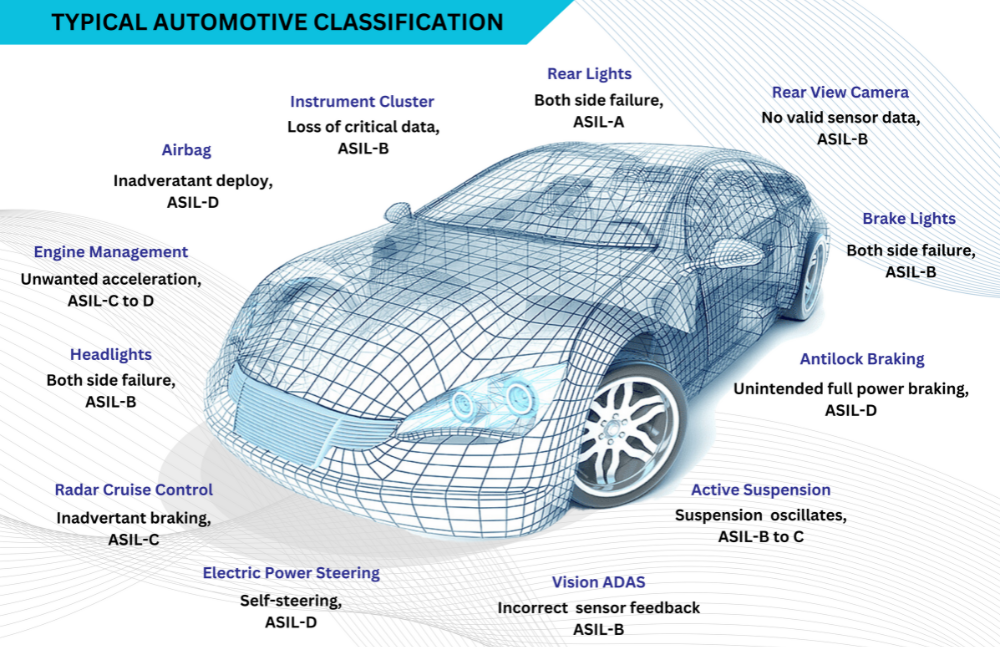

Functional Safety

Ensuring passenger safety by proactively considering measures that identify the hazards at the system, software, and hardware level through ISO26262.

Cybersecurity

ISO 21434 standard can help identify external and internal threats to passengers and mitigate them with proactive measures, ensuring a secured product.

Unlock the Future of Mobility with Unparalleled

Software Excellence

(Schedule a 30-Minute Consultation with our Experts)

We are Trusted by 20+ Clients and

5+ Countries Worldwide

We are Trusted by 20+ Clients and

5+ Countries Worldwide

Our Solutions

Transform Software Supplier Quality Management: Introducing K-SMART for Enhanced Transparency and Efficiency

Elevate supplier quality with K-SMART, our Integrated Software Supplier Quality Framework that enhances transparency in supplier performance, revolutionizing your workflow by streamlining, monitoring, and reporting throughout product development.

Proactive Quality Management is our Priority

Empower your Journey towards Perfection With Us!

(Schedule a 30-minute Consultation with our Experts)

Process Doctors

Software Wellness starts here, No Bitter Pills Required

We are a team triggered by our passion for addressing the critical challenges of software product quality improvement, and supplier software quality management. We aim to connect the dots between systems, software, development processes through product-aided consultancy and an agile working framework.

40+ ASPICE and FUSA Assessments

80+ Process Consulting Projects

Resources

Latest Blogs

- Read More

Case Studies

- Read More

Videos

- Read More

Connect with Us

Knot Consulting GmbH

76689 Keplerstr. 8,

Karlsdorf – Neuthard, Germany

Solutions

- IPF

- K-Smart

- ASPICE

- FUSA

- Cybersecurity